Get A Quote

Rotomized pickleball Production Process

Rotomized pickleball Production Process

The production process of rotomolding pickleballs involves several key steps that transform raw materials into finished products. Below is a detailed overview of the process:

1. Material Preparation

Selection and Mixing: The raw materials, typically high-density polyethylene (HDPE) or similar polymers, are carefully selected and mixed with any necessary additives or pigments to achieve the desired color, durability, and performance characteristics.

2. Loading the Mold

Precise Measurement: Accurate amounts of the prepared material are measured and loaded into the rotomolding mold. This ensures consistent product quality and avoids excess or insufficient material.

Locking the Mold: Once the material is loaded, the mold is securely locked to prevent leakage during the rotation and heating process.

3. Heating and Rotation

Heating Cycle: The mold is heated while simultaneously rotating around two perpendicular axes (both rotating and orbiting). This process, known as rotational molding or rotomolding, allows the material to evenly distribute and adhere to the mold's surface.

Plasticization: As the mold rotates and heats, the plastic material gradually melts and plasticizes, forming a uniform layer on the mold's interior surface.

4. Cooling

Forced Cooling: Once the plastic has melted and adhered to the mold, the mold is cooled, usually through forced ventilation or water sprays. This step solidifies the plastic and prepares it for removal from the mold.

5. Demolding and Trimming

Demolding: After cooling, the mold is opened, and the pickleball shell is carefully removed. This process requires precision to avoid damaging the newly formed product

Trimming: Any excess plastic or imperfections on the surface of the pickleball are trimmed away, ensuring a smooth and uniform finish.

6. Final Inspection and Packaging

Quality Control: Each pickleball undergoes a thorough quality control check to ensure it meets the required standards for weight, bounce, and durability.

Packaging: The finalized pickleballs are packaged in appropriate containers or bags, ready for shipping and distribution.

Key Points

- The rotomolding process is highly automated but still requires skilled operators to ensure precise material handling, mold locking, and demolding.

- The quality of the raw materials and the accuracy of the measurements play crucial roles in determining the final quality of the pickleballs.

- Continuous monitoring and quality control measures throughout the production process ensure consistency and reliability in the final products.

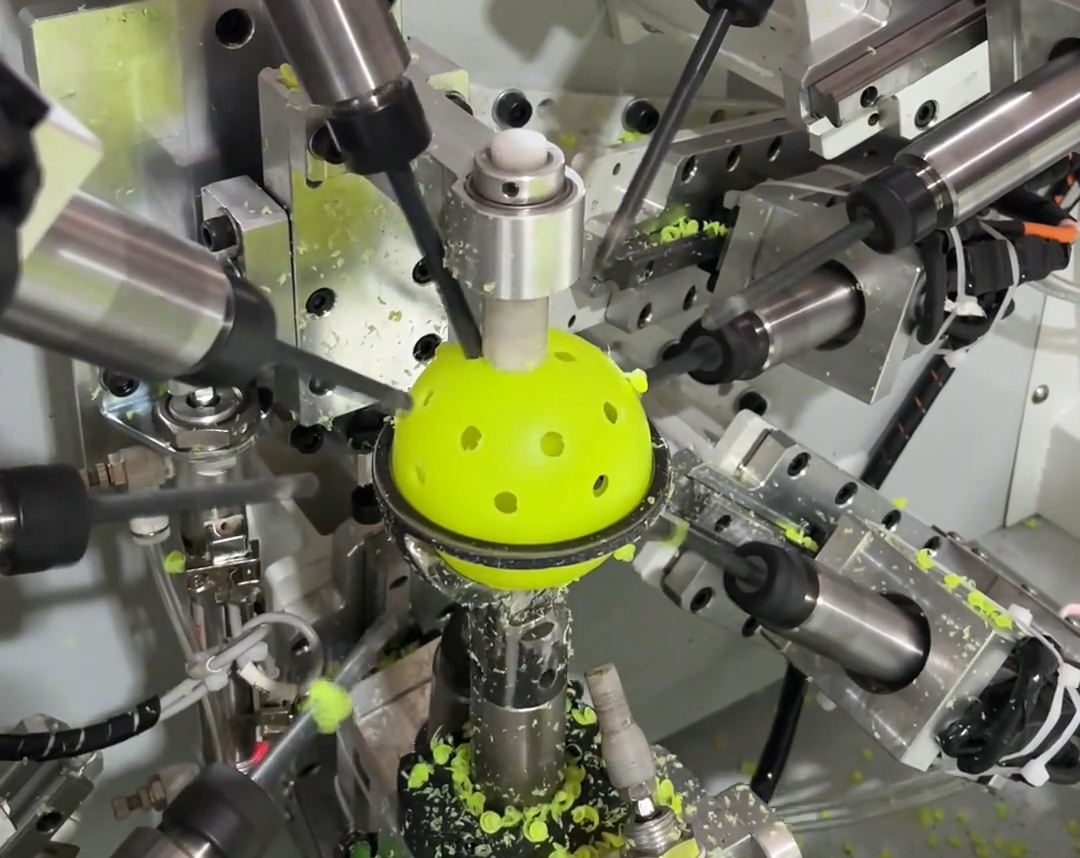

The drilling process for rotomolding pickleballs involves several precise steps to ensure the holes are accurately positioned and cleanly executed. Here's an overview of the process :

1. Preparation

- Equipment Setup: Ensure that the drilling machine or tool is properly set up and calibrated. Select the appropriate drill bit size based on the desired hole diameter.

- Safety Precautions: Wear protective gear such as safety glasses and gloves to prevent injuries during the drilling process.

2. Marking the Position

- Positioning the Ball: Securely place the rotomolding pickleball on a stable work surface or in a specialized fixture designed for drilling.

- Marking the Hole: Use a pencil, marker, or other non-permanent tool to mark the exact location where the hole will be drilled. This ensures accuracy and prevents misalignment.

3. Drilling the Hole

- Starting the Drill: Carefully align the drill bit with the marked position and slowly start the drilling process. Apply steady pressure while maintaining a straight and even drilling motion.

- Controlling the Speed: Adjust the drilling speed as necessary to avoid overheating the plastic or causing the drill bit to slip. This helps ensure a clean and smooth hole.

- Depth Control: Monitor the depth of the hole to ensure it is consistent with the desired specifications. Stop drilling once the desired depth is achieved.

4. Post-Drilling Inspection

- Cleaning the Hole: Remove any debris or plastic shavings from the hole using compressed air or a soft brush. This ensures that the hole is clear and ready for use.

- Quality Check: Inspect the hole for any imperfections, such as cracks, tears, or uneven edges. If necessary, use a file or sandpaper to smooth out any rough spots.

5. Final Inspection and Packaging

- Overall Inspection: Perform a final inspection of the pickleball to ensure that the hole is properly positioned and does not affect the overall integrity or performance of the ball.

- Packaging: Once the pickleball passes inspection, package it appropriately for shipping or storage.

Notes:

- The drilling process for rotomolding pickleballs requires precision and attention to detail to avoid damaging the ball or creating an uneven hole.

- The specific drilling equipment and techniques used may vary depending on the manufacturer and the desired hole specifications.

- Always follow safety protocols and use the appropriate protective gear when working with drilling equipment.

By following these steps, manufacturers can produce rotomolding pickleballs with accurately positioned and cleanly drilled holes, ensuring optimal performance and durability for players.

FAQs

1. Can I customize the size and dimensions of the rotational molding machine to fit my production facility?

2. Is it possible to customize the mold size and weight for producing specific products?

3. Can the mechanical arm of the rotational molding machine be customized to suit different production needs?

Custom Solutions with Rotational Molding

Discover the advantages of rotational molding, explore the materials and machinery utilized in our process, and learn how we tailor custom solutions to meet your specific requirements through our rotomoulding technique.

Discover the advantages of rotational molding, explore the materials and machinery utilized in our process, and learn how we tailor custom solutions to meet your specific requirements through our rotomoulding technique.