Get A Quote

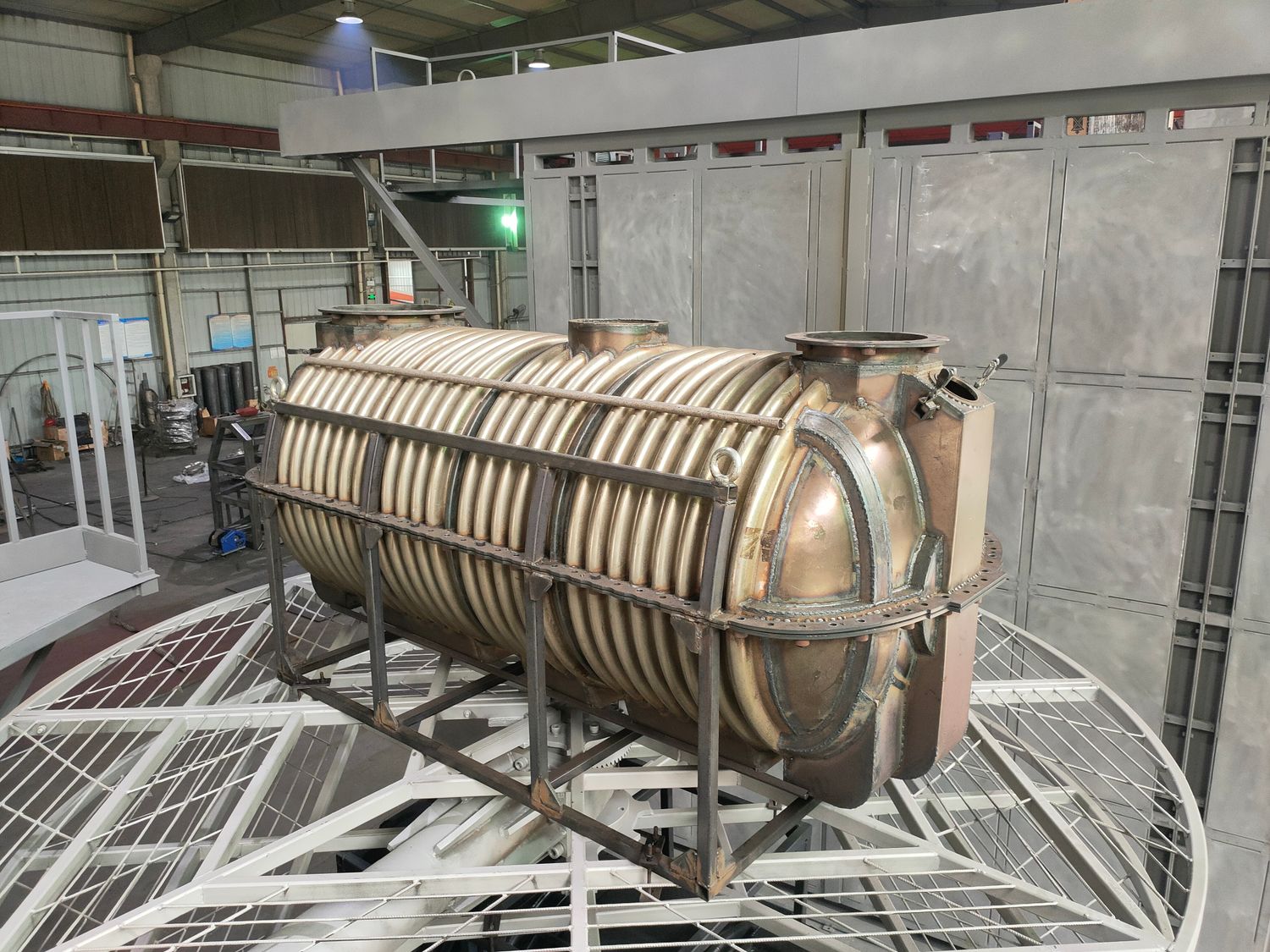

Rotational Steel Mold

Customized

Customize your rotational molding machine to meet all your requirements

Swift Delivery

Normally 30-45 Days

Shelf Life and Service

1-year free maintenance (18-month guarantee for motor, frequency converter, PLC, and boom)

Rotational Molding Mold Maintenance Essentials

Rotational Molding Mold Maintenance Essentials

Proper daily maintenance of rotational molding molds is crucial, as it directly impacts the quality of the molded products and the lifespan of the molds. However, due to a lack of relevant maintenance knowledge, many operators in rotational molding production tend to neglect the protection of these molds, leading to product quality issues and mold damage, which can result in unnecessary losses for the company. Therefore, it is essential to pay close attention to the daily maintenance of rotational molding molds and diligently perform the following tasks:

Proper daily maintenance of rotational molding molds is crucial, as it directly impacts the quality of the molded products and the lifespan of the molds. However, due to a lack of relevant maintenance knowledge, many operators in rotational molding production tend to neglect the protection of these molds, leading to product quality issues and mold damage, which can result in unnecessary losses for the company. Therefore, it is essential to pay close attention to the daily maintenance of rotational molding molds and diligently perform the following tasks:

Regularly inspect the molds and products, and promptly repair any surface scratches, dents, peeling, or cracks.

When demolding, use soft tools to avoid forcefully prying with hard tools, which can damage the mold, especially Teflon-coated molds, where local peeling would require complete re-coating, causing production delays.

If the mold develops scratches or burrs, use fine oil stones or sandpaper for polishing, rather than files.

Periodically clean the mold flange area to ensure sealing, but use soft tools to avoid damaging the parting line.

Store the molds in a dry, well-ventilated, and flat location, check the mold frame for cracks or damage, and ensure proper mold installation to prevent deformation from the mold's own weight.

After production, promptly remove the mold from the rotational molding machine and place it on a flat surface, avoiding long-term hanging on the machine, which can cause deformation and uneven loading on the equipment.