Get A Quote

Unveiling the Magic of Carrousel Rotomolding Machines

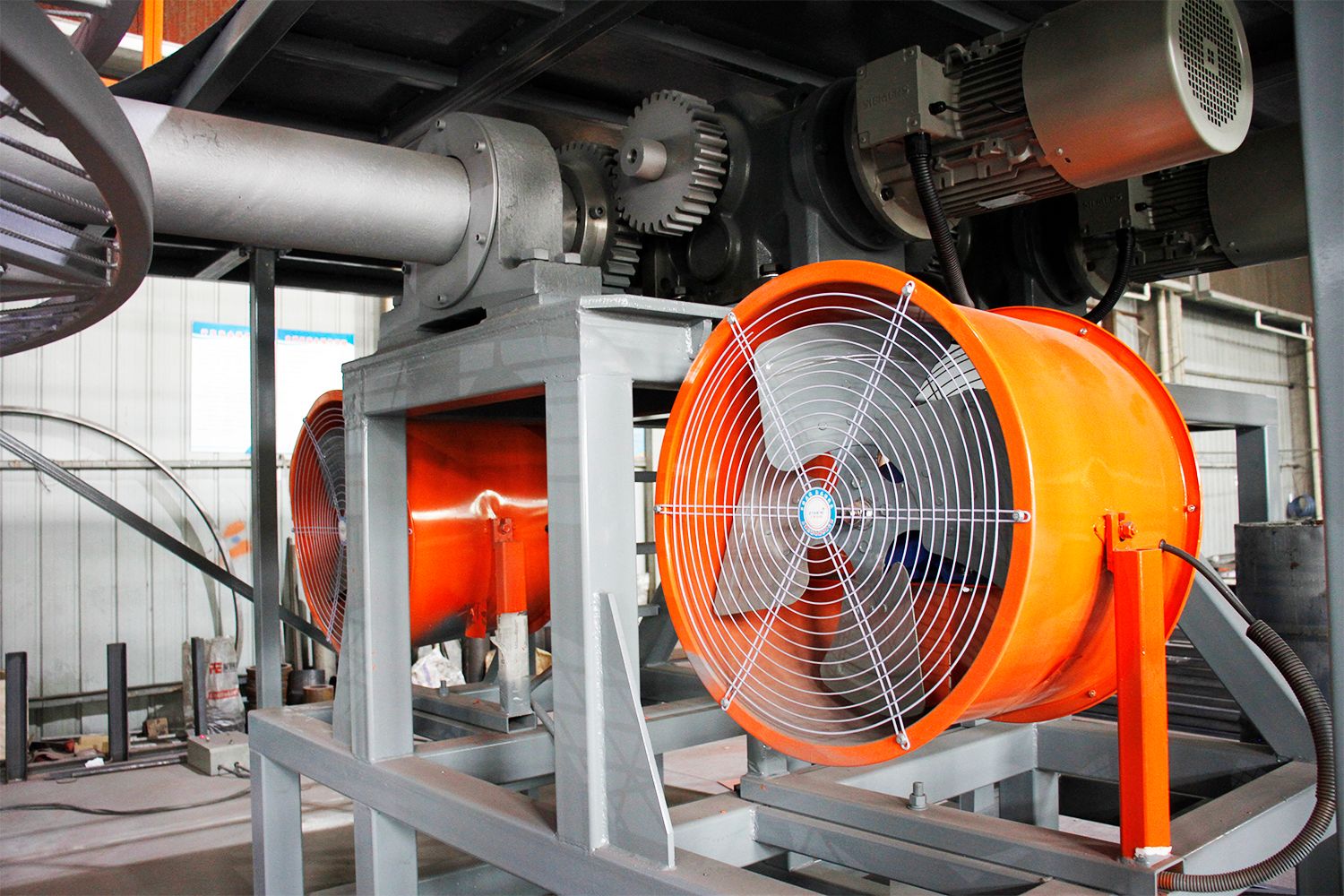

In the dynamic realm of manufacturing, innovation continually pushes boundaries and redefines possibilities. One such marvel in industrial machinery is the carrousel rotomolding machine. This sophisticated apparatus operates with precision and efficiency, revolutionizing the process of creating hollow plastic products. In this blog, we delve into the intricacies of this fascinating machine, exploring its components, functionalities, and impact on the manufacturing industry.

Understanding the Carrousel Rotomolding Machine

At the heart of the carrousel rotomolding machine lies a design epitomizing ingenuity and engineering excellence. Central to its operation are three mechanical cars that form the backbone of the system. These cars, equipped with various mechanical arms, play a crucial role in shaping the final product. The four types of mechanical arms commonly used in carrousel rotomolding machines are the straight arm, L arm, U arm, and frame arm. Each arm type offers distinct advantages and applications, contributing to the machine's versatility.

The Working Principle of Carrousel Rotomolding Machines

To understand the magic behind these machines, it’s important to break down the basic working principle. A Carrousel Rotomolding Machine operates by rotating a mold around one or more axes while simultaneously heating the mold to allow the plastic resin to soften and fuse to the mold's interior surface. After this, the mold is cooled, and the part is removed once solidified.

The key difference between a Carrousel Rotomolding Machine and traditional systems lies in its multi-stage, rotating process. This allows manufacturers to achieve better consistency and quality, particularly for large batches, all while reducing manual labor and the risk of human error.

Here’s a step-by-step breakdown of the typical process:

Mold Loading: The molds are placed onto the carousel in a set pattern, ready to be rotated through the system.

Heating Phase: As the carousel rotates, the molds are slowly heated in an oven. The plastic material inside melts, coating the interior of the mold.

Cooling Phase: After heating, the molds enter a cooling station where the plastic solidifies into the desired shape.

Ejection: Once cooled, the molds rotate to the ejection station where the finished products are removed.

Cycle Repeats: The carousel then rotates back to the loading phase to start the next production cycle.

This process is highly automated, requiring minimal manual intervention, which significantly reduces the risk of errors and boosts productivity.

The Role of Mechanical Arms

Straight Arm

The straight arm, with its streamlined design, excels in handling simple molds and products requiring uniform rotation during the molding process. Its straightforward yet effective structure makes it valuable for producing a wide range of plastic components.

L Arm

The L arm, characterized by its perpendicular bend, accommodates molds necessitating intricate movements and precise control. This arm type is adept at maneuvering through complex geometries, ensuring accurate and consistent molding outcomes.

U Arm

The U arm, with its curved configuration, is ideal for molds that demand gentle and sweeping motions. Its versatility allows for the production of hollow products with varying shapes and sizes, showcasing the machine's adaptability to diverse manufacturing requirements.

Frame Arm

The frame arm, known for its robust frame and stability, is tailored for molds requiring additional support and reinforcement during the rotation process. This arm type enhances the machine's capability to produce sturdy and durable plastic products, meeting stringent quality standards.

Enhancing Efficiency with Additional Stations

Beyond the mechanical components, the carrousel rotomolding machine can be further optimized with specialized stations. The cooling station plays a pivotal role in the post-molding phase, facilitating the gradual cooling of products to ensure uniformity and structural integrity. Additionally, the loading and unloading station streamlines the production process by automating the transfer of molds and finished products, reducing manual intervention and enhancing operational efficiency.

Advantages of Carrousel Rotomolding Machines

The carrousel rotomolding machine offers a multitude of benefits that position it as a preferred choice in the manufacturing industry. Its ability to produce hollow plastic products with exceptional precision and consistency sets it apart from traditional molding techniques. The flexibility afforded by the various mechanical arms enables manufacturers to cater to diverse design requirements, expanding the scope of possibilities for product development.

Moreover, the incorporation of cooling and loading/unloading stations optimizes production workflows, minimizing downtime and maximizing output. By enhancing operational efficiency and streamlining processes, carrousel rotomolding machines contribute to cost savings and improved productivity, making them a valuable asset for businesses seeking to stay competitive in an ever-evolving market.

Conclusion

The carrousel rotomolding machine stands as a testament to innovation and excellence in industrial machinery. With its intricate design, versatile mechanical arms, and advanced functionalities, this machine has redefined the manufacturing process, empowering businesses to create high-quality plastic products with precision and efficiency. As technology continues to advance, the carrousel rotomolding machine remains a beacon of progress, driving innovation and shaping the future of manufacturing.

In a world where quality and efficiency are paramount, the carrousel rotomolding machine emerges as a game-changer, revolutionizing production processes and setting new standards for excellence in the industry.

FAQs

What is a carrousel rotomolding machine?

A carrousel rotomolding machine is an advanced industrial apparatus designed for the efficient production of hollow plastic products through rotational molding.

What are the main components of a carrousel rotomolding machine?

The main components include mechanical cars, various types of mechanical arms (straight arm, L arm, U arm, frame arm), cooling stations, and loading/unloading stations.

How does the straight arm in a carrousel rotomolding machine work?

The straight arm handles simple molds requiring uniform rotation, making it effective for producing a wide range of plastic components.

What advantages does the U arm offer in the carrousel rotomolding process?

The U arm, with its curved design, provides gentle and sweeping motions ideal for creating hollow products with diverse shapes and sizes.

Why are cooling stations important in a carrousel rotomolding machine?

Cooling stations are crucial for gradually cooling the molded products, ensuring uniformity and maintaining structural integrity.

How do carrousel rotomolding machines enhance production efficiency?

These machines enhance efficiency by automating mold transfers, reducing manual intervention, and optimizing production workflows, leading to cost savings and increased productivity.